STERDILL EQUIPMENTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to STERDILL EQUIPMENTS P.LTD.

Steam Sterilizer

USES :

Fabwell Sterilizers are suitable for Hospitals, clinics, Laboratory etc. They are designed for safe & efficient sterilization of various items such as wrapped or unwrapped goods, instruments & utensils etc ..

CONSTRUCTION :

The sterilizer has double walled (inner chamber & Jacket) type design, which allows preheating of chamber by jacket steam.

The chamber is constructed of heavy-duty stainless steel 304/316.

DOORS :

The Sterilizer is supplied with single door or double doors made of 304/316 S .S. The door has provision, which prevents. opening of door when the chamber is under pressure.

Fittings

Washer Di Infector

|

INSTRUMENT WASHER / DISINFECTOR It is fitted with revolving sprays, driven by a water pump. It is operated with circulating water for washing and disinfection. The process includes-prewashing with cold water, detergent wash, hot water rinse (disinfection) at 85o C. The process is automatically controlled in a time regulated sequence bt a programme card; and there is also provision for Manual Operation. The unit is of stainless steel construction having single OR two doors, suitable for electric OR steam heating. Overall Size : 800mm x 800mm x 1500mm H. |

Cssd Planning And Execution

Complete Planning ,Supply & Execution for Hospital of Central Sterilization Supply Department ( CSSD ) & Theatre Sterile Supply Unit (TSSU) supply of Sterilizers, Washers alongwith various units such as..

Ultrasonic Cleaner

Drying Cabinets

Work table

Various trolleys & baskets

Work table with Sink

Storage Racks

Packing Table

Pass Boxes of Stainless Steel to exchange material between Clean & Unclean area, with or without HEPA filter etc

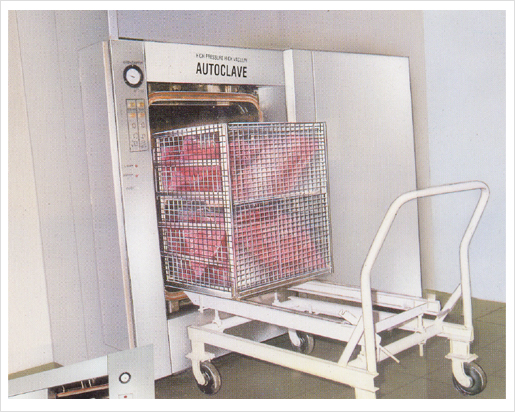

Waste Autoclave

STERILIZATION PROCESS :

The sterilization of biomedical waste is done with the help of saturated steam at the temperature of 121°C/ 134°C.

The sterilizer is operated by steam supplied from the central boiler or by in -built electric steam generator.

HPHV process ensures good penetration of the steam & reduces the cycle time by evacuating air by vacuum pump.

Optional automatic control unit to control & indicate pressure, temperature & time during the the process.

The loading & unloading carriage is made of stainless steel and it is designed to slide easily from chamber to trolley.The floor trolley is

made of M.S. (Painted).

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.